Uncovering EBITDA Improvements Through Operational Excellence and Pricing Strategy in High SKU Mix Manufacturing

In the competitive landscape of manufacturing, getting pricing right is crucial. This challenge is amplified in organizations that have a high SKU mix and a need for numerous quotes, or with complex inventory management and pricing strategies.

Implementing data-driven processes is essential for making consistently optimal pricing choices. By better understanding manufacturing costs and efficiency points, organizations can price effectively while ensuring profitability. This article explores the intersection of operational excellence and pricing strategy in high-frequency quoting environments and offers a path forward for optimal pricing strategies.

Pricing in a High-Frequency Quoting Business

Pricing is one of the most important pieces of a business to get right and can be the difference between winning a business contract or losing business. Pricing can also be the difference between operating profitability and operating at a loss.

In businesses with a high SKU mix that requires a high volume of quotes, there are many more opportunities to get pricing right…or wrong. With a diverse range of products or services requiring different pricing based on factors like customization, order size, or customer requirements, or in dynamic pricing situations, setting up formalized data-driven processes is key for consistently making optimal pricing decisions.

To do so, you must:

- Understand manufacturing costs

- Identify efficiency points

This information enables the ability to price to win. Winning means more than just getting the contract; it means acquiring the business in a profitable way.

Manufacturing Operational Excellence & Understanding

Most manufacturers face significant market competition, so it is imperative that the business drives efficiency in operations to compete profitably. The process requires an understanding of production costs and how each characteristic of a job impacts these costs. Things like order size, customer lead time, demand variability, unique raw materials, customer specific QA requirements, and other factors, can all impact production costs.

Organizations typically have a basic understanding of standard costs. Elevating this level of understanding, however, can become a competitive advantage. Understanding efficiency drivers enables an organization to price more optimally. A manufacturer should:

- Understand where things add cost in the production process

- Understand where to drive more efficiency in the production process

When we understand the efficiency drivers, we are able to direct customers to the optimal points. This allows the manufacturer to price more competitively while still pricing at a profitable margin. Read on for an example of how I implemented this approach for one of my clients.

case study

Manufacturer of Medical Equipment

Context: A manufacturer of medical equipment typically provided quotes for new parts at three standard quantity levels: 25 units, 50 units, and 100 units.

As the volume levels increased, the price per piece went down. This process was driven by a combination of the market standard and a “this is how it’s always been done” sentiment.

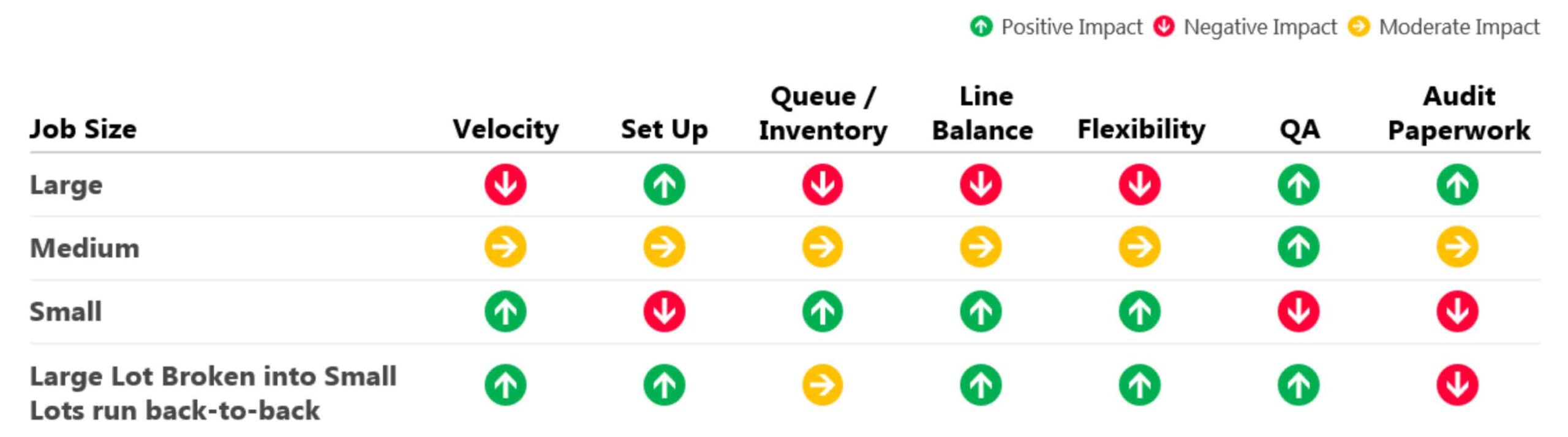

Analysis: When we analyzed the production process, it became clear that these quantity levels did not in fact align with any manufacturing efficiency levels. As the volumes went up, there were economies of scale in terms of setup being amortized over a larger volume. But within the process were inefficiencies not immediately obvious that prevented the organization from reaching total efficiency.

There were challenges for some production processes as the job sizes grew. We saw larger work-in-process (WIP) material on the floor, bigger bottlenecks at constraints, and less flexibility in the flow of the material. Due to feedback from the production floor on these challenges, larger orders were being broken into multiple smaller jobs to streamline production.

Figure 1.1 Job Size Impact on Production Efficiency

The planning team scheduled the smaller jobs back-to-back to maintain the setup efficiency while allowing jobs to move quickly through the plant. However, when reviewing historical data, it became clear that these jobs required multiple setups, as they were not being run in line. The organization was offering customers a discount for ordering larger quantities, but not capturing the efficiency of running the material as a larger job.

Action and Result: Rather than just quoting at the standard quantity levels historically used, we wanted to quote at the most efficient quantity levels. This required a real understanding of the production process and where we could drive more efficiency.

For this organization, keeping the machines running in 24-hour increments allowed them to ensure setups were on the first shift with the most experienced machinist. This enabled quicker setups with fewer quality challenges. This scheduling shift also ensured there was enough productivity from a job in relation to the set-up time.

Instead of standard quantity levels, we used the production methods for each part to calculate the most efficient quantity multiples by part. This allowed us to price at quantity levels, allowing the business to produce these parts efficiently, ultimately resulting in competitive pricing for the customer.

Operational Excellence & Understanding Combined with Pricing Strategy: Driving a Competitive Advantage

When we combine lean operational excellence and understanding of what is driving efficiency (or inefficiency) with pricing strategy, the result is competitive advantage. We can price at the optimal quantity points which will be more competitive than standard levels.

This concept goes much further than just quantity-level pricing. This methodology is applicable across various characteristics that impact manufacturing efficiency. For example:

Lead Time

If a customer has a shorter lead time requirement, the business has less flexibility to schedule in the most optimal way. When pricing, we can provide pricing for the lead time required by the customer, while also providing a discount for a longer lead time option. The manufacturer is therefore able to provide a more competitive price while maintaining profitability when the customer wants to keep a shorter lead time.

QA Requirements

Quality requirements can vary dramatically between customers, resulting in a significant impact on manufacturing cost and efficiency. If a customer has very stringent quality requirements that, for example, require every unit to be tested, this needs to be incorporated into pricing. By providing the customer discount options – switching to a QA sample of the lot instead of each piece – we can highlight the cost of this requirement for the customer.

Offering efficiency visibility for customers is a competitive advantage since most manufacturers only provide the quote based on the customer requirements.

To achieve the competitive advantage brought on by combining operational excellence and understanding with data-driven pricing strategy, a manufacturer needs to do the following:

- Thoroughly understand cost drivers and the characteristics that drive efficiency or inefficiency.

- Combine cost drivers with a commercial discussion on how to incorporate these levers into a pricing strategy.

- If this is brought to the customer as an avenue to reduce inflationary pressure, it can be a win-win: the manufacturer can enjoy better margins and the customer is getting a more competitive total cost.

Working with an experienced Catalant Expert like me to run this exercise can help yield the advantages this approach offers.

Find optimization Experts now.

Let’s TalkMeet the Author

Stacy Sifleet is the president of Pricing Velocity, a boutique pricing analytics consultancy. Pricing Velocity has helped clients drive value through targeted pricing strategies since 2019. Stacy is also a partner at Supply Velocity where she helps her clients identify and implement Supply Chain improvements. Stacy started her career at Kearney and developed a deep expertise in supply chain and operations. This operations background combined with her pricing and analytics experience give her a unique skill set to help organizations improve their profitability.

Want to work directly with Stacy? Contact us to learn how.