How the largest contract manufacturer in the orthopedic industry tackled rising operational costs.

The Problem

In the United States, an estimated 126.6 million Americans are affected by musculoskeletal conditions. Many of these adults are treated through orthopedic surgery, creating a booming market for orthopedic and medical devices. Recent estimates show a potential growth up to $43.1 billion by 2024.

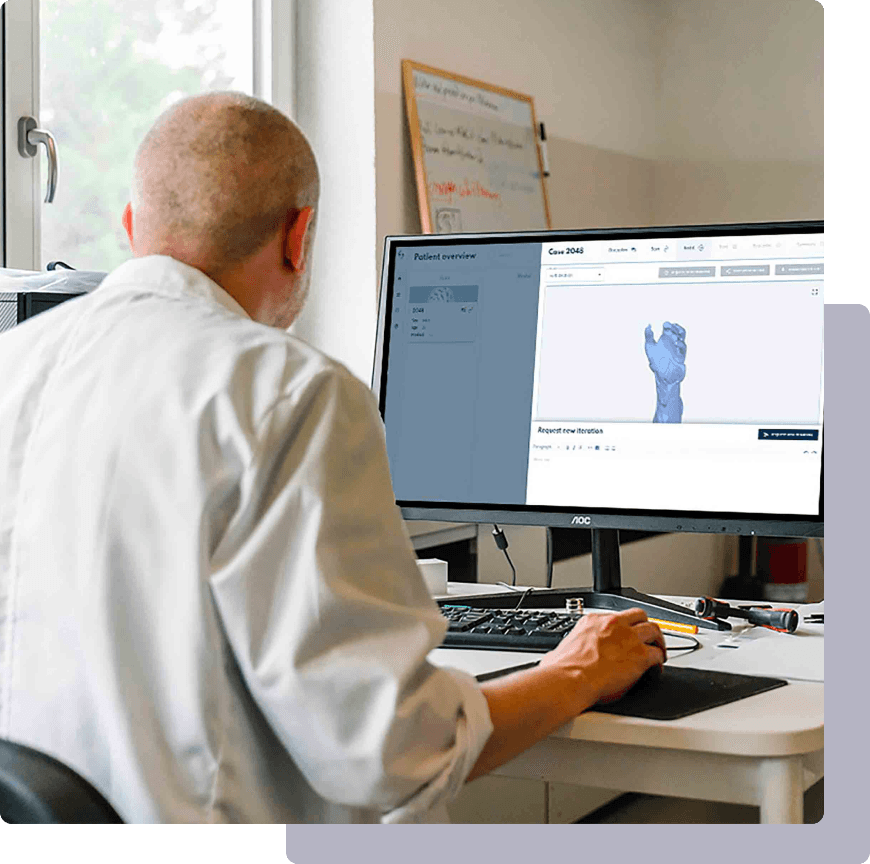

Tecomet, a leading metal and materials innovator, is in the middle of it all. The largest contract manufacturer in the orthopedic industry, Tecomet designs and manufactures many of the devices used in the roughly 7 million orthopedic surgeries occurring each year.

To meet this demand, the company employs over 2,500 people, operating at 16 facilities across the globe. But, as the world’s population ages and demand for the orthopedic and other medical devices that Tecomet manufactures grows, the company is faced with a challenge of how to keep pace.

When addressing increasing manufacturing and labor costs brought about by the COVID-19 pandemic and ensuing labor market fluctuations, Tecomet needed to apply the same forward-thinking mentality to operational design that it already excelled at with product design.

Faced with wage inflation causing a rise in operating expenses and competition over labor exacerbating the issue, Tecomet’s EVP of Strategy & Business Transformation, Mat Ackerman, needed to consider how the company could automate key processes, a complex challenge.

But Ackerman knew he couldn’t solve the problem alone. Hiring a full-time head to support solving this problem would be too slow because of the steps involved in recruiting, onboarding, and hiring. “The business world has never been more dynamic than what we’ve seen over the last 2+ years,” Ackerman said. “The ability to respond to key issues with expertise and agility is paramount to success.”

A former management consultant, he knew that bringing in an outside point of view could provide new perspectives to the problem in front of him. Instead of looking towards a large, traditional consulting firm, Ackerman leaned on independent consultants hired through Catalant’s Marketplace.

“The business world has never been more dynamic than what we’ve seen over the last 2+ years. The ability to respond to key issues with expertise and agility is paramount to success.”

Mat Ackerman

EVP, Strategy & Business Transformation![]()

The Solution

Ackerman worked with different independent consultants from Catalant’s Marketplace on several projects. The work ranged from exploring how to automate processes to lessen the importance of direct labor and balancing that with a strategy to retain and develop current employees to building out a plan to tackle raw material inflation procurement – a challenge when considering the breadth of Tecoment’s operations.

Because Ackerman was flexing up to tackle specific challenges, he was able to get the right consultant for each challenge, hiring consultants with strong analytical skills for some projects and subject matter experts with specific knowledge who could collaborate with internal resources for others.

Overall, Ackerman’s work with the independent consultants sourced through Catalant have helped improve EBITDA, which he attributes to better visibility within Tecoment’s product portfolio, stronger engagement with the Sales team, and strategic and operational improvements in S&OP. And, as a bonus for Ackerman–some of the consultants that he hired for fractional work converted into full-time employees after working on a project at the company.

These improvements all help Tecomet maintain its role as a leading manufacturer within the medical device space, and position the company for an instrumental role in the growth of the orthopedic industry in the coming years.

Read More Case Studies

-

How DFC Global Corp Expanded the Reach of their Non-traditional Financial Products with Catalant

Read Case Study : How DFC Global Corp Expanded the Reach of their Non-traditional Financial Products with Catalant -

How Perch Surged Ahead with Precision Problem Solving from Catalant and Achieved 21,675% ROI

Read Case Study : How Perch Surged Ahead with Precision Problem Solving from Catalant and Achieved 21,675% ROI

Ready to start your success story?

Connect with independent consultants and subject-matter experts who deliver quality work when you need it.