“All In and People First” Lean Leadership: Leadership Considerations for Lean Success

Although Lean has produced exceptional results in companies such as Toyota and Danaher, most organizations do not achieve lasting Lean success. Organizations that limit Lean to manufacturing or isolated projects without making the necessary changes to organizational culture and supporting business processes may experience short-term improvements but rarely sustain them over the long term. In contrast, research demonstrates that companies that succeed with Lean do so by adopting an “all in and people first” mindset.

To achieve true, lasting transformation, organizations must take an “all in and people first” approach, embracing Lean Transformation leadership—a leadership mindset and system that aligns strategy, culture, and operations at every level of the enterprise. This leadership-driven approach embeds Lean into the way the organization thinks, operates, and improves. Whether you are an executive leading change, a manager guiding teams, or a Lean practitioner seeking to make a real impact, understanding how leadership drives transformation as part of an “all in and people first” approach is the key to sustainable success.

The “all in and people first” Lean framework

Lean is defined as a state of business health characterized by minimal waste and maximum process performance, ultimately delivering value to customers and stakeholders. A Lean organization makes jobs safer, easier, and more productive; fosters growth; and creates new opportunities, much like a healthy individual benefits from good habits.

While Lean can be applied to all business processes, it is most commonly associated with manufacturing, where it delivers tangible improvements in safety, quality, lead time, on-time delivery, fill rate, equipment utilization (OEE), inventory, and productivity.

Top-performing Lean companies employ a balanced “all in and people first” framework where:

- “All in” – Top leadership actively “leads”

- “People first” – Employees are empowered and demonstrate process ownership

As part of this, leadership leads with a servant leadership style and prioritizes “respect for people” to create trust and ownership within process teams, ensuring local process teams are empowered, held accountable, and rewarded for their Lean outcomes. In these systems, empowered teams take ownership of their local Lean processes using an “inside-out” approach, seeking external Lean expertise and support only as required. This contrasts with the traditional “outside-in” model, where changes are driven by supervision, often resulting in poor team ownership.

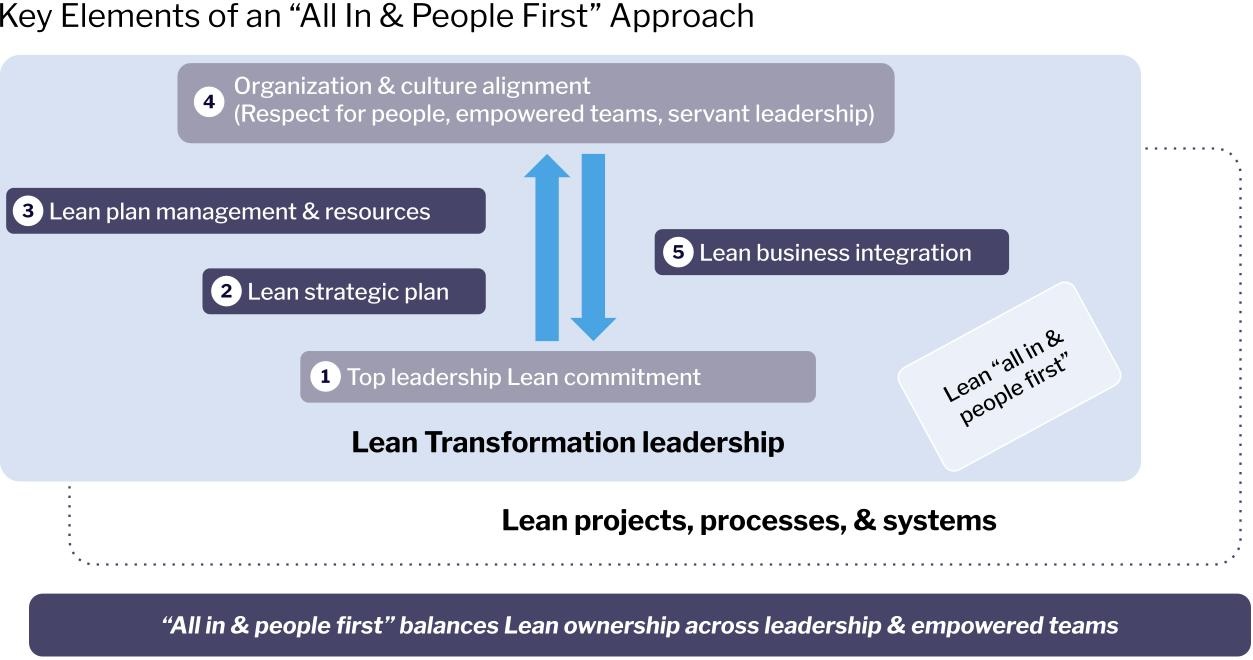

This framework is underpinned by a Lean strategic plan, dedicated resources, plan management, and the full integration of Lean thinking and practices throughout the business (see Figure 1).

Figure 1 – Lean Transformation leadership balances top leadership and people empowerment

These “all in and people first” Lean business systems—exemplified by the Toyota Production System (TPS), Danaher Business System (DBS), and FLIGHT DECK (GE Aerospace Lean business system)—create the conditions for Lean through their culture, processes, and systems. As Taiichi Ohno, architect of the TPS, famously stated: “If you are going to do TPS, you must do it all the way. You also need to change the way you think. You need to change how you look at things.” (Taiichi Ohno, Toyota Production System—Beyond Large Scale Production, 1988)

The four elements of Lean Transformation

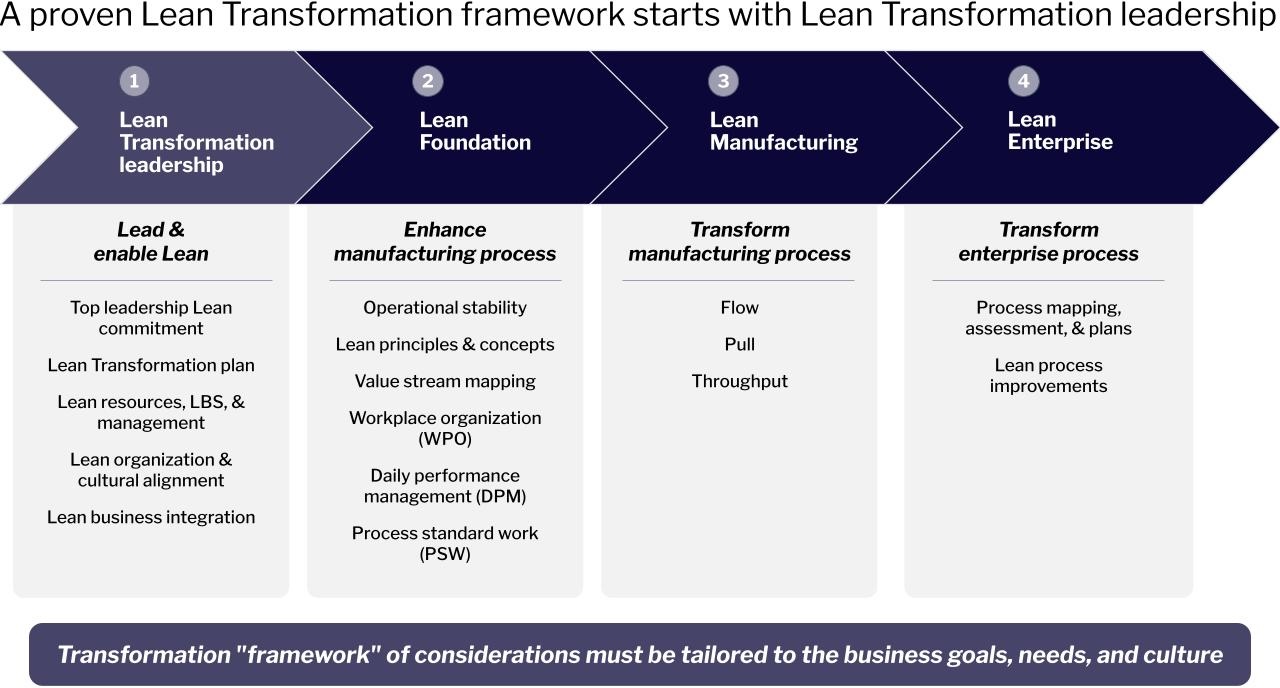

Four critical elements contribute to a proven Lean Transformation framework. These include:

- Lean Transformation leadership: Success in Lean begins with unwavering commitment from top leadership, a clear transformation strategy, effective Lean management, organizational and cultural alignment, and integration of Lean within the business.

- Lean Foundation: Establishing Lean and empowering teams starts with operational stability, Lean principles and concepts, value stream mapping (VSM), workplace organization (WPO), daily performance management (DPM), and process standard work (PSW).

- Lean Manufacturing: This element dramatically improves flow, pull systems, throughput, and overall performance.

- Lean Enterprise: Lean is extended beyond manufacturing to drive continuous improvement across all enterprise processes.

Figure 2 shows how the four elements of this proven Lean Transformation framework fit together, with Lean Transformation leadership as the first and most critical element.

Figure 2 – Lean Transformation framework

Without a strong commitment to Lean Transformation leadership, it is often difficult for teams to successfully build a Lean Foundation and transform manufacturing and enterprise processes. Through an “all in and people first” leadership approach, leaders and the organization work in balance to co-own Lean success and proactively mitigate common failure mechanisms through:

- Going “all in” – Setting Lean as a top strategic priority, not just another “program of the year”

- Leaders are trained practitioners and lead Lean effectively — not just “hand waving.”

- A realistic strategic improvement plan is established with a coordinated “all hands on deck” approach for “critical few” priorities — not the traditional silo-driven plan focused on the “trivial many” priorities.

- A shift in financial mindset from cost minimization to “investing” in success.

- Lean PMO and Lean business system (LBS) are investments made to drive the Lean transformation.

- Lean is practiced in the C-suite, not just in the factory.

- Putting “people first” – Driving Lean as a cultural change rather than as just another process improvement approach

- Empowered and accountable teams take full “ownership.”

- A servant Leadership philosophy supports employees at all levels.

- The hiring process prioritizes recruiting Lean expertise at all levels.

- Teams are incentivized and share in the improvement results.

- The organization owns Lean Transformation through change management engagement.

Together, these elements create the environment necessary for lasting results.

The key components of Lean Transformation leadership

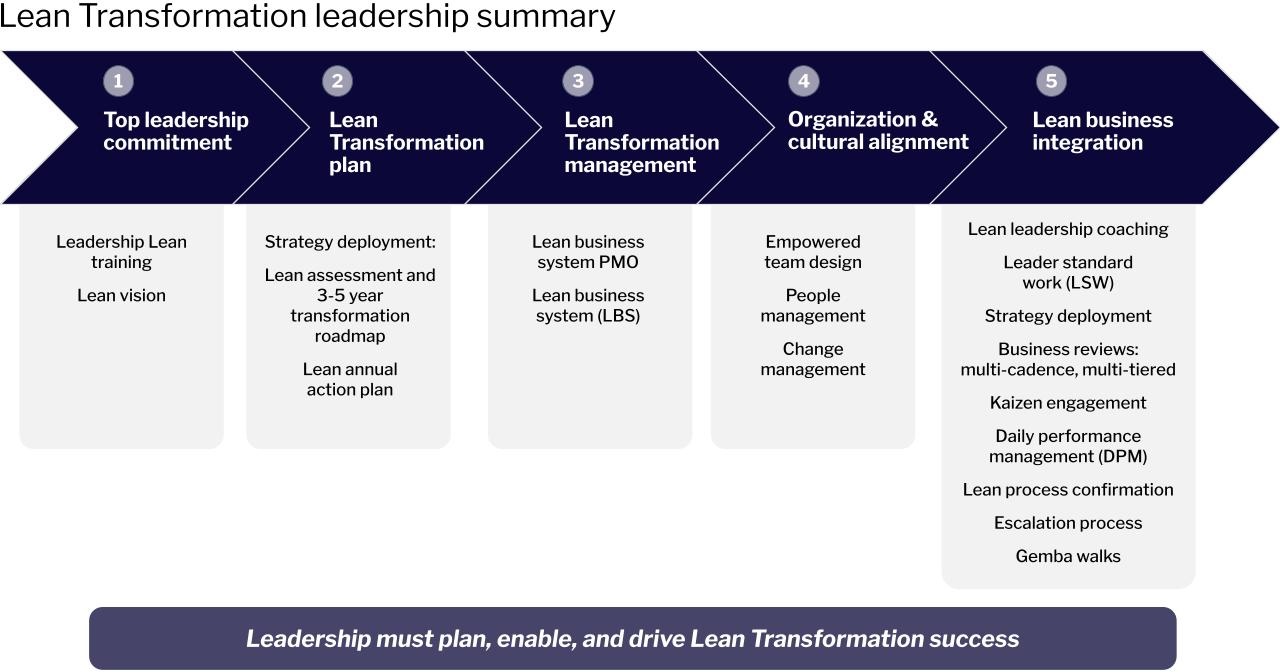

Within Lean Transformation leadership, there are five key components to success, as illustrated in Figure 3. These components outline the steps leadership teams must take to support a successful Lean Transformation. Each component is examined below.

Figure 3 – Lean Transformation leadership

Elements of Lean Transformation leadership

- Top leadership commitment: Top and all leadership make a real “all in and people first” commitment, including participating in Lean leader practitioner training and solidifying a Lean vision. This is “the destination.”

- Lean Transformation plan: A strategic, comprehensive Lean business strategy is developed and broken down into achievable bites with a strategic deployment plan (or equivalent). This is “the route map.”

- Lean Transformation management: Plan achievement is managed by a Lean PMO with a Lean leader and specialists, supported by a Lean business system (LBS) and daily plan-do-check-act (PDCA) management and governance. This is “the command center.”

- Organization and cultural alignment: This is the start of empowering a high-performing Lean organization. Stable, empowered teams are designed and deployed around value streams and processes. New hires are added at every level that bring Lean leadership and experience; bonus compensation is added based on performance and Lean execution; and backups and succession plans are established for all critical roles. This is where “the high-performing team owns their process performance.”

- Lean business integration: Every day, the common Lean values and processes, including those that are difficult to sustain, are reinforced. This includes servant leadership, Gemba walks, etc. This is “the Lean business system standard work.”

Each of these five elements is critical for creating leadership systems and organizational culture that nurture Lean processes and drive long-term success. These five elements are explored in greater depth below.

1: Top leadership commitment

For a Lean Transformation to be successful, leadership must prioritize Lean as a non-negotiable element of business strategy—a “wake-up call” for the entire organization. This includes:

- Leadership Lean training: All leaders, starting from the top, must transition from merely “talking the talk” to credibly “walking the talk” as Lean advocates. This is achieved through a combination of classroom training, practical exercises, simulations, and best practice visits to organizations that exemplify Lean principles.

- Lean vision and communication: Leaders must clearly and frequently communicate the business commitment to Lean, as in the following examples:

- GE Aerospace: Per Larry Culp, CEO of GE Aerospace and prior CEO of Danaher, “FLIGHT DECK is the framing of the next step of our Lean Transformation. FLIGHT DECK is our proprietary Lean operating model. This is the way we’re going to run the business… We’ve decided to go with FLIGHT DECK, something we rolled out just a month ago with our senior leadership team from around the world in Dayton to make sure we seize the moment, and we accelerate from here the Lean Transformation that has been gathering momentum because we’re going to need all of that positive effect as a public company.” (GE Aerospace Investor Day 2024). Larry Culp’s approach is a particular testament to the power of leading Business success through Lean, given his successes at both Danaher and GE Aerospace.

- Toyota Production System: The complete elimination of waste in pursuit of the most efficient methods.

- Danaher Business System: “The Danaher Business System (DBS) is our system of continuous improvement and the culture that makes it work.”

- Ford Motor Company: Through 2014, the company’s vision statement read, “People working together as a Lean, global enterprise to make people’s lives better through automotive and mobility leadership.”

2: Lean Transformation plan

Lean commitment is supported by a long-term strategic transformation plan—typically spanning three-to-five years and ideally linked to business strategy. While this high-level plan sets the direction, detailed planning and management are addressed in the Lean Transformation management phase. This includes:

- Lean assessment and three- to five-year roadmap: Together, the assessment and roadmap span:

- Lean assessment: Assess the leadership, culture, processes, and systems for Lean risks and opportunities and as input to the Lean plan.

- Lean pilot/model cell/line: Select an area with minimal risk and moderate impact to demonstrate Lean methodologies and win over leadership and the organization with rapid impact. Strive for maximum speed and scope to include core Lean concepts, focusing on people first, then process.

- Lean deployment: Tier deployment to align with business strategy across business units, plants, value streams, and processes. Include an initial one-year kaizen plan.

- Lean organization and cultural change management: Implement key changes in organization team design and people management, and include the change management needed to realize those changes.

- Lean business system (LBS): Develop, deploy, and support cultural practices and Lean processes and systems, sequenced according to the deployment plan.

- Lean business integration: Implement key changes to embed Lean principles into every aspect of business leadership and operations.

- Lean annual action plan: From the three- to five-year strategic plan, an annual action plan is developed across model work areas, deployment and kaizen activities, change management, and the Lean business system.

3: Lean Transformation management

This is the basis of realizing the plan. It encompasses:

- Lean business system PMO:

- Resources are assigned to support, manage, and deliver the Lean plan. The Lean top leader owns the overall strategy, management, and realization of Lean, reporting directly to the top business leader, engaging in leadership meetings, and coaching key stakeholders. Other resources include Lean Senseis and specialists who lead kaizens, coach leaders and teams, and drive “inside-out” Lean success.

- Plan management takes place at quarterly, monthly, weekly, and daily levels, all guided by the long-term Lean Transformation plan. Plan-do-check-act (PDCA) is the foundation of Lean Transformation program management. The kaizen plan is coordinated business-wide and driven primarily by strategic deployment, with some local flexibility. Integration of Lean values and practices is planned for each business unit, plant, and value stream.

- Governance is ensured through regular engagement and reviews with key stakeholders, including the Lean executive sponsor, steering group, and deployment area leaders.

- Lean business system (LBS): The LBS is developed, deployed, and supported in line with the deployment plan, embedding Lean practices, processes, and systems throughout the organization. The LBS’s architecture includes a work breakdown structure (WBS) for its culture, processes, and system elements with assigned owners, initial deployment plans, and key dates. Standard formats, systems, tools, and rules ensure consistency. Development plans specify owners, deployment dates, and areas, supported by comprehensive training materials. Training materials ensure consistency of learning and deployment.

4: Organization and cultural alignment

This is the “secret sauce.” The transition and balance of Lean ownership across leadership and empowered process teams is the most critical determinant of Lean success. The core of this is a people-first mentality and servant leadership style. When organizations truly support empowerment and accountability, Lean thrives; when they do not, teams quickly sense insincerity and disengage. This includes:

- Empowered team design: High-performing team design is essential, with stable, value-stream-aligned work teams and minimal personnel changes.

- People management: From how talent is hired to how individuals are recognized, high-performing teams working in Lean environments must be set up for success.

- Hiring: Focus on Lean aptitude, teamwork, results orientation, and flexibility.

- Backup plans: Ensure coverage for all key roles.

- Succession planning: Maintain continuity after departures.Compensation: Offer competitive base pay (preferably in the first quartile), meaningful bonus opportunities, and rewards to motivate and retain talent.

- Rewards and recognition: Use spot and period awards, plus public recognition, to show appreciation for outstanding contributions.

- Change management: This includes the communication, engagement, and timing of key changes to team structure, people management, and change management processes.

- Communication: One-way messaging to inform stakeholders, specifying message, media, sender, recipients, and timing. Topics include the Lean Transformation plan, achievements, performance, and more, delivered via verbal, electronic, written, or visual means.

- Engagement: Two-way interactions to foster Lean ownership, such as leadership “skip-level” meetings, focus groups, “lunch and Lean” sessions, one-on-one coaching, and regular check-ins.

5: Lean business integration

To sustain Lean, leadership must embed Lean into all aspects of the business, ensuring daily reinforcement. This includes:

- Lean leadership coaching: Provide on-the-job coaching by the Lean PMO team to all leaders for new, critical Lean leadership, including all of the following topics within this Lean business integration section.

- Leader standard work (LSW): Use LSW to provide a systematic routine for leaders to integrate Lean leadership, with comprehensive accountability through a checklist of critical tasks.

- Strategy deployment: Attain Lean strategy across business units and functions as one element of a well-managed strategy deployment. Ensure the Lean plan is followed as it progresses and is continually replanned, never losing focus on the “critical few” strategic thrusts.

- Business reviews: Drive Lean thinking into business planning and performance reviews. Align KPIs and manage meetings with goals, clear agendas, a PDCA routine, and a problem-solving focus for critical issues.

- Kaizen engagement: Engage every leader and associate in Kaizens at a minimal cadence (e.g. quarterly) and in appropriate roles (planning/prep, kickoff, event team member, debrief).

- Daily performance management (DPM): Engage associates in multi-cadence, multi-tiered DPM.

- Lean process confirmation: Ensure leaders oversee and help process teams sustain Lean processes.

- Escalation process: Escalate and resolve issues effectively and in a timely manner based on priority and type.

- Gemba walks: Engage all leadership in Gemba walks to better understand process waste drivers and opportunities. Connect with employees, observe processes, ask questions, and offer support.

Sustaining Lean for the long-term

Lean Transformation is a continuous journey that depends on leadership commitment, cultural alignment, and the disciplined application of Lean principles across all functions. When organizations truly live the “all in and people first” philosophy, they unlock operational excellence as well as a deeper sense of purpose and engagement across teams.

However, even the most dedicated organizations can benefit from expert guidance to accelerate progress and sustain results. External partners bring proven frameworks, real-world experience, and objective insight to help leaders assess maturity, identify gaps, and implement tailored strategies that ensure Lean becomes part of the company’s DNA.

Are you ready to go all in—and people first—on Lean Transformation?

Connect with an expertMeet the Author

Jim Schoen is a Catalant consultant and Lean Practitioner with more than 35 years of Lean leadership experience as a consultant and industry executive across diverse sectors and geographies. As Managing Principal Consultant at FRC Group Inc., Jim leads strategic Lean Transformations to enable major enterprises, PE portfolio companies, and start-ups to optimize operations and improve performance. He holds a Master of Business Administration from the UCLA Anderson School of Management and a Bachelor of Science in Mechanical Engineering from Rensselaer Polytechnic Institute.

Related Articles

Share Article