Service Offering

Lean Six Sigma for Cost Reduction

When market pressures demand rapid cost reduction and performance improvement, generic consulting approaches fall short. Organizations need proven operational excellence from experts who have delivered results across hundreds of implementations. Catalant's Lean Six Sigma specialists bring decades of hands-on manufacturing and operations experience from leading companies to help you:

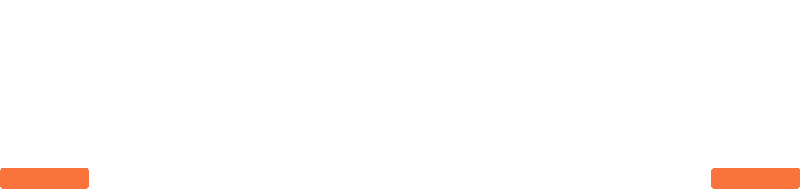

APPROACH

Operational Transformation with a Proven Methodology

01

Rapid diagnostic assessment

Conduct comprehensive analysis of current state operations, identifying high-impact improvement opportunities and establishing baseline metrics across all target sites and processes.

02

Strategic program design

Design customized Lean Six Sigma deployment strategy, including site prioritization, tool selection, impact projections, and sustainable management system architecture.

03

Pilot implementation

Execute focused pilot programs at selected sites to validate approach, demonstrate quick wins, and build internal capability while refining deployment methodology.

04

Wave-based deployment

Roll out proven methodology across additional sites in strategic waves, ensuring knowledge transfer, local adaptation, and sustainable implementation at scale.

05

Capability building & sustainment

Establish internal Centers of Excellence and Academies, train internal teams to Green and Black Belt levels, and implement ongoing governance systems to ensure long-term success.

WINNING TOGETHER

Lean Six Sigma Use Cases

Problem

A specialty chemicals manufacturing plant was facing a critical $23.7M shortfall against its annual profit objective. The site operated three separate business units with inconsistent processes, creating operational silos that prevented efficient resource allocation and drove up fixed costs. Without immediate intervention, the plant would miss its financial targets and face potential restructuring.

Action

A team of Experts established and led a comprehensive Project Management Office to orchestrate the turnaround effort. The program encompassed 8 primary workstreams managing over 30 sub-projects focused on identifying operational synergies across business units, coordinating cross-functional teams, implementing best practice standardization, and creating flexible “flow-to-work” resource allocation systems, all while maintaining production quality and safety standards.

Results

The engagement achieved:

- $12M in fixed cost reduction

- Additional $4-5M projected savings by year-end

- Standardized processes across three business units enabling flexible resource deployment

- Sustainable operational framework supporting continued cost optimization beyond the engagement period

Automotive Supply Chain Excellence

A major automotive coatings facility was struggling with 9+ day manufacturing turnaround times and poor on-time delivery to a high-volume truck plant customer, while maintaining excessive 30-day inventory levels for primary paint colors. Experts partnered with the resident Six Sigma team to implement consumption-based replenishment systems, delivering Lean Practitioner Training and facilitating targeted Kaizen events to redesign production workflows. The transformation achieved remarkable results: manufacturing turnaround dropped to 1.5 days (85% improvement), on-time shipment performance reached 99%, and inventory was reduced to just 5 days' supply—freeing up significant working capital while strengthening the critical OEM relationship.

Unionized Chemical Plant Optimization

A specialty chemical plant's production unit was underperforming with poor productivity in critical areas. Targeting $3.5 million in annual cost savings, the Expert served as project manager, developing standardized work practices for processes while navigating complex union negotiations with both local and national representatives. Through collaborative engagement with plant management and union leadership, the Expert successfully negotiated agreed-upon standards that were integrated into daily performance metrics, ultimately delivering $5 million in annual savings—43% above target—primarily through improved operations and maintenance productivity and optimized contractor services.

FEATURED EXPERTS

Featured Lean Six Sigma Leaders

Joakim Y.

Ex-McKinsey Sr. Expert, Ex-Carlsberg Breweries and SD Worx

Leads operational transformations in the Life Science and Consumer Goods industries

Mike F.

Ex-McKinsey senior specialist, Ex-Nestle

Senior specialist in manufacturing operations; Leads global OpEx programs; lean transformation and continuous improvement coach

Yorgos F.

Ex-McKinsey Associate Partner, Ex-Rolls-Royce, DENSO

Operations Practice leader, specialized in semiconductor, aerospace, and automotive

Achieve operational excellence that drives bottom-line results.

Connect with dozens of Experts qualified and ready to do this work.