Embracing Continuous Supply Chain Transformation

Have you ever wondered why it seems like companies are always in a state of supply chain transformation? It can feel like a perpetual change rollercoaster, one that impacts the top and bottom lines. But transformation isn’t simply about top-line growth or bottom-line pressures. It’s about adapting to changing market landscapes, black swan events like the pandemic, technological advancements, and shifting customer behaviors.

Organizations of all sizes face a critical question: “Why transform?” Answering that question requires digging deeper, exploring reasons like peer competition, obsolete business models, survival challenges, or a bold vision to lead the industry. Planning horizons have also shortened as companies assess their marketplace position more frequently, making it feel like transformation is happening more often.

On top of that, an organization must decide whether it wants to be the trailblazing leader setting the industry pace or follow the path someone else has already paved. The answer hinges on factors like how much risk they’re willing to embrace for that exponential growth or if they’d rather play it safe, settling for steady gains.

Here’s the interesting thing – there’s no right or wrong answer to either of those questions. It all depends on a cocktail of factors – the capital commitment, the thumbs-up from the board of directors, their workforce’s capacity to weather challenges while keeping the business ship afloat, the pressure of survival, the capability of their processes and systems, and, last but not least, the ability to embrace change with open arms. It’s like putting together a puzzle where every piece counts, and the picture only emerges when they’ve figured out how to adapt and absorb change for sustainable gains.

Business transformations, if planned and executed well, can provide needed change in the infrastructure (organizational or systemic) or the organizational culture (or both) that can enable company growth with profitable sales. Transformations led by global system changes can result in standardized and integrated global systems that provide visibility and single source of truth for quick and rational decisions. In addition, it provides the system functionality and flexibility to unlock other growth opportunities while positioning the company with competitive advantage.

Technology Influence in Supply Chain Transformations

Supply chain transformations can vary significantly in their reliance on technology and systems. Some are heavily technology-led transformations, while others are tech-enabled but primarily driven by partner ecosystem collaborations.

In most cases, a tech-led transformation is required when organizations have grown rapidly and have relied on manual processes and small-scale tech landscapes which inhibit further growth. Additionally, organizations that have grown organically over the years often end up with disparate systems that prevent them from taking advantage of company-wide synergies. These systems may not be scalable, lack flexibility to accommodate new business models, require significant investment to maintain or upgrade, have obsolete software versions needing enhancement, or have process inefficiencies that increase labor costs and SG&A, ultimately impacting customer experience.

On the other hand, non-tech transformations are usually driven by strategic events such as organizational changes for workforce consolidation, global centralization or decentralization, global expansion into new geographies or product categories, and workforce cultural innovation for continuous improvement, such as Lean principles. While these initiatives may necessitate some technological changes or integration, their scope is often limited to specific project requirements impacting one or more functional groups. In contrast, tech transformations, often co-led by IT leaders, typically entail company-wide changes.

It is also possible for a non-tech transformation to lead to tech transformations. For instance, an M&A integration or divestiture could ultimately require the acquired or acquiring company to adapt to the other company’s systems and processes, resulting in a transformative change for the company being impacted.

Technology-Led Transformations

These transformations are driven by the implementation of advanced technology platforms. This might include the deployment of new ERP systems, the integration of sophisticated warehouse management systems (WMS), Customer Relationship Management (CRM) or the adoption of cutting-edge logistics software. The goal is to enhance visibility, streamline operations, and improve overall efficiency through technological innovation.

Case Study: Technology-Led Transformation

Context: A company was experiencing rapid growth, adding billions in revenue in less than 4 years. During its earlier stages, when the company was generating millions in revenue, the primary focus was on boosting the top line. This intense drive for growth led to the neglect of a comprehensive backend system infrastructure. As the business expanded in complexity and scale, the company relied on quick fixes and patchy solutions for its supply chain systems.

Analysis: The company’s ability to sustain rapid growth was severely constrained. Expansion into new product categories, channels, and markets introduced complexities that the existing system couldn’t handle. Inefficiencies began to affect day-to-day operations, necessitating a larger workforce to maintain operations, which in turn increased costs and SG&A. It became clear that a comprehensive overhaul of the supply chain systems was necessary.

A consensus was reached that the existing legacy system had become a bottleneck and had to be replaced with an integrated, best-in-class enterprise resource planning (ERP) system. The goal was to create an infrastructure capable of supporting both organic and inorganic growth.

Action and Result: The first step was to develop a business case to seek investment commitment from the board. A cross-functional business and IT team supported by a System Integrator was formulated to assess current processes and evaluate change readiness. This involved diving deep into systems, processes, and workforce dynamics to identify opportunities and shape the future operational state.

The defined future state requirements served as the foundation for the RFP to evaluate and select an ERP system. Leading this organization through the system selection process was challenging, as different departments advocated for solutions that best met their specific needs. Debates emerged over costs, functionality, necessary enhancements, ease of deployment, and the long-term viability of each solution. A separate RFP effort was undertaken to select a system integrator, as the selected partner would impact the total cost of ownership, including deployment and steady-state maintenance.

After a year-long process, a final recommendation was presented to the C-suite executives. This included the total investment, ROI, a deployment roadmap, and a business readiness assessment to mitigate the risks associated with such a large-scale transformation.

Partner Ecosystem-Led Transformations

These transformations are driven by the strategic expansion and optimization of the supply chain partner ecosystem. This could involve reconfiguring distribution networks, forming new partnerships with 3PL providers, or enhancing collaboration with suppliers and distributors. These transformations are tech-enabled, but the focus is on leveraging external relationships to improve speed-to-market, reduce costs, and enhance service levels.

Case Study: Partner Ecosystem Collaboration-led Transformation

Context: A Retail/Wholesale company struggled to maintain its margin and sales targets with wholesale account customers due to increasing supply chain costs, diminished speed-to-market, lower customer satisfaction, and rising chargebacks. At the same time, the company was navigating a channel transition strategy to balance its conflicting physical retail, e-commerce, and wholesale channels. Previous attempts to transform the wholesale supply chain had failed to yield significant results.

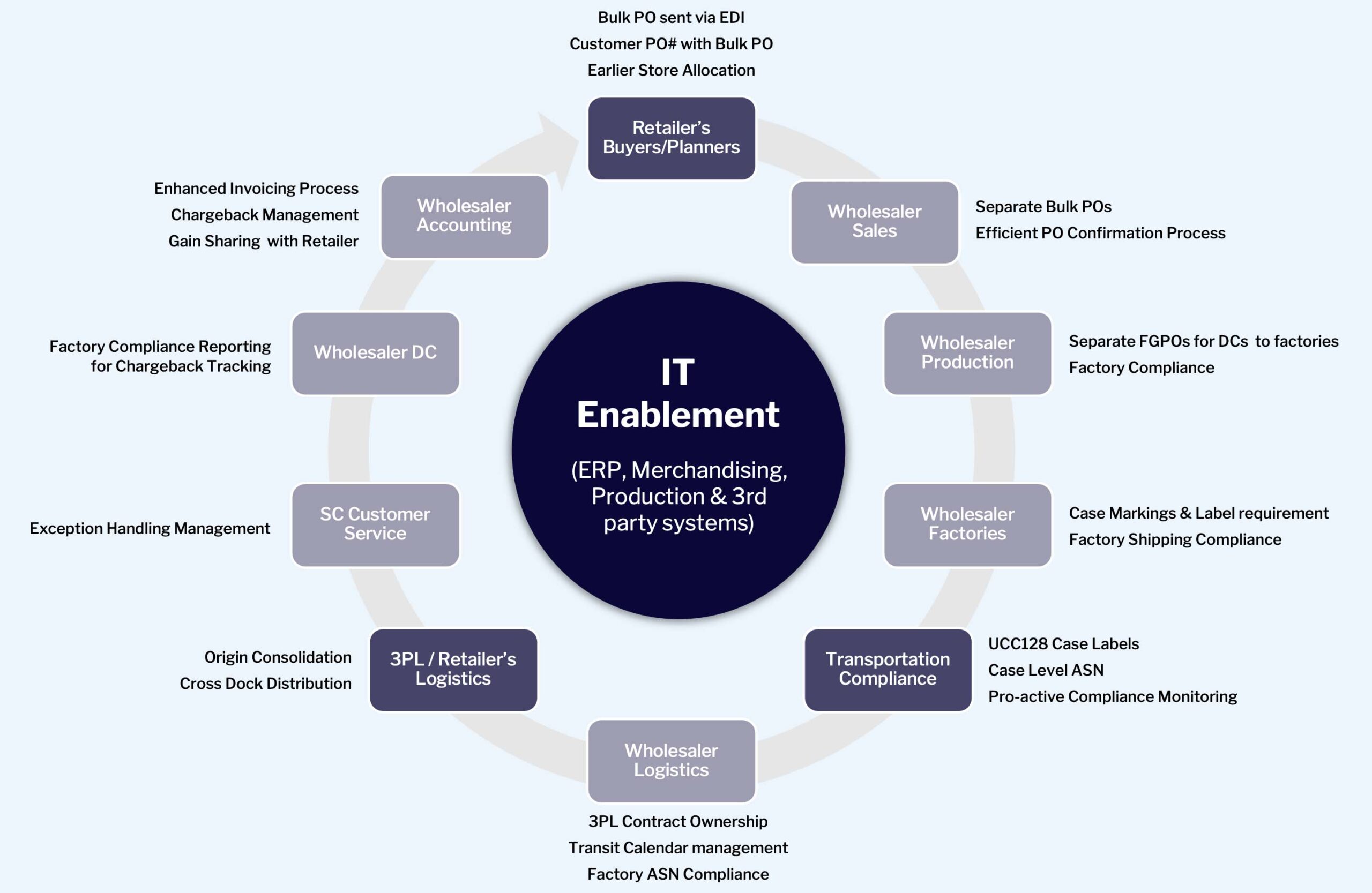

Analysis: Upon in-depth discovery, it was determined that a foundational overhaul was necessary—from order placement to delivery at the customer’s retail stores, which was lacking in previous attempts. A convincing, bold and holistic supply chain transformation business case for a pilot category was necessary rather than just a distribution and a logistics play. It would require process and system changes encompassing not only existing external partners involved (customer, manufacturer, original consolidator, transportation, warehouse, merchandising, ERP systems) but bridging new relationships with the customer’s merchandising department and 3PL partner.

Action and Result: Upon executive approval, a large cross-functional team with internal & external partners was established to manage this program, organizing multiple sub-work streams to:

- Re-engineer the order-to-cash process.

- Bypass the traditional distribution network in favor of a prioritized retailer’s private brand network.

- Enhance collaboration across all partners involved, from manufacturers to 3PL operators.

- Align on a gain-sharing partnership with the customer to compensate them for the resulting incremental effort on their teams

In just over a year, from business case development to execution, the program exceeded all goals and expectations, laying the foundation to expand the model to other product categories and wholesale customers. It resulted in improved speed-to-market by 7-10 days, increased annual sales by $1.5 million, reduced distribution costs by $400K, lowered markdown allowances, integrated shop-floor-ready store delivery and presentation, and enhanced the overall customer experience.

In Closing

In today’s complex and ever-changing environment, companies must become comfortable with continuous supply chain transformation.

The phenomenon of companies continually pursuing special projects to stabilize their operations has fundamentally transformed how they function. This constant state of adaptation has led to a significant increase in project-based roles and a growing reliance on consultants and fractional executives. These external experts bring specialized skills and experience with minimal learning curve, helping companies address critical needs quickly and efficiently.

The case studies highlighted here illustrate how strategic leadership and expertise in both technology and ecosystem led supply chain transformations can deliver substantial business benefits and position companies competitively for sustained growth. However, navigating through these complex transformations require a highly experienced industry veteran who has scars on the back and can provide stead-fast leadership throughout the journey.

Find supply chain Experts now.

Let’s TalkMeet the Author

Ketul Patel is the founder and president of OMIIA Consulting, a boutique consultancy based in New Jersey that specializes in supply chain strategy, distribution network planning, logistics operations optimization, S&OP planning, 3PL operations management, and ERP/WMS/planning system implementations. OMIIA’s mission is to help companies “Enable their Growth and Optimize Profitability via Supply Chain Excellence.” Ketul has held supply chain leadership positions at Deloitte and various corporate Retail/CPG companies. As both a hands-on operator and strategic thinker, he has served as a trusted thought partner in identifying opportunities and developing innovative solutions. Additionally, he has led teams in managing transformative projects from inception to execution. Ketul has a Bachelor’s in Industrial Engineering from MS University in India, and a Masters in Industrial Engineering from University of Houston and is a certified SCOR-Professional.

Want to work directly with Ketul? Contact us to learn how.

Related Articles

Share Article