Accelerating Process Improvement in Retail with Digital Twins

Retailers are under increasing pressure to grow sales, improve customer experience, and streamline operations, despite rising costs, evolving consumer expectations, and labor shortages. Yet many core processes, such as staffing and order fulfillment, remain anchored in rigid legacy systems. Traditional improvement methods like process mapping are slow, labor-intensive, and insufficiently data-driven to keep pace with the speed and flexibility that today’s environment demands. Retailers need faster, more adaptive ways to redesign operations and respond to real-time market signals.

A more dynamic alternative is emerging: process digital twins. Unlike process mining, which analyzes what has already happened, digital twins simulate future scenarios. They allow leaders to test operational changes virtually before implementing them in the real world.

For example, a digital twin for in-store staffing can help managers evaluate different scheduling models, identify trade-offs, and predict which patterns are most likely to optimize performance, reduce labor costs, and raise sales conversion rates.

By shifting from retrospective analysis to forward-looking simulation, digital twins offer a practical way to navigate complexity and improve agility in retail operations.

Three ways to build a process digital twin

Building an effective process digital twin starts with clarity about the outcomes it’s meant to improve, both for the customer and the business. Whether the “customer” is a shopper, a downstream partner, or an internal department, the modeling process should focus on their experience and needs. Ultimately, the goal is to improve sales, reduce capacity bottlenecks and costs, and increase the organization’s agility.

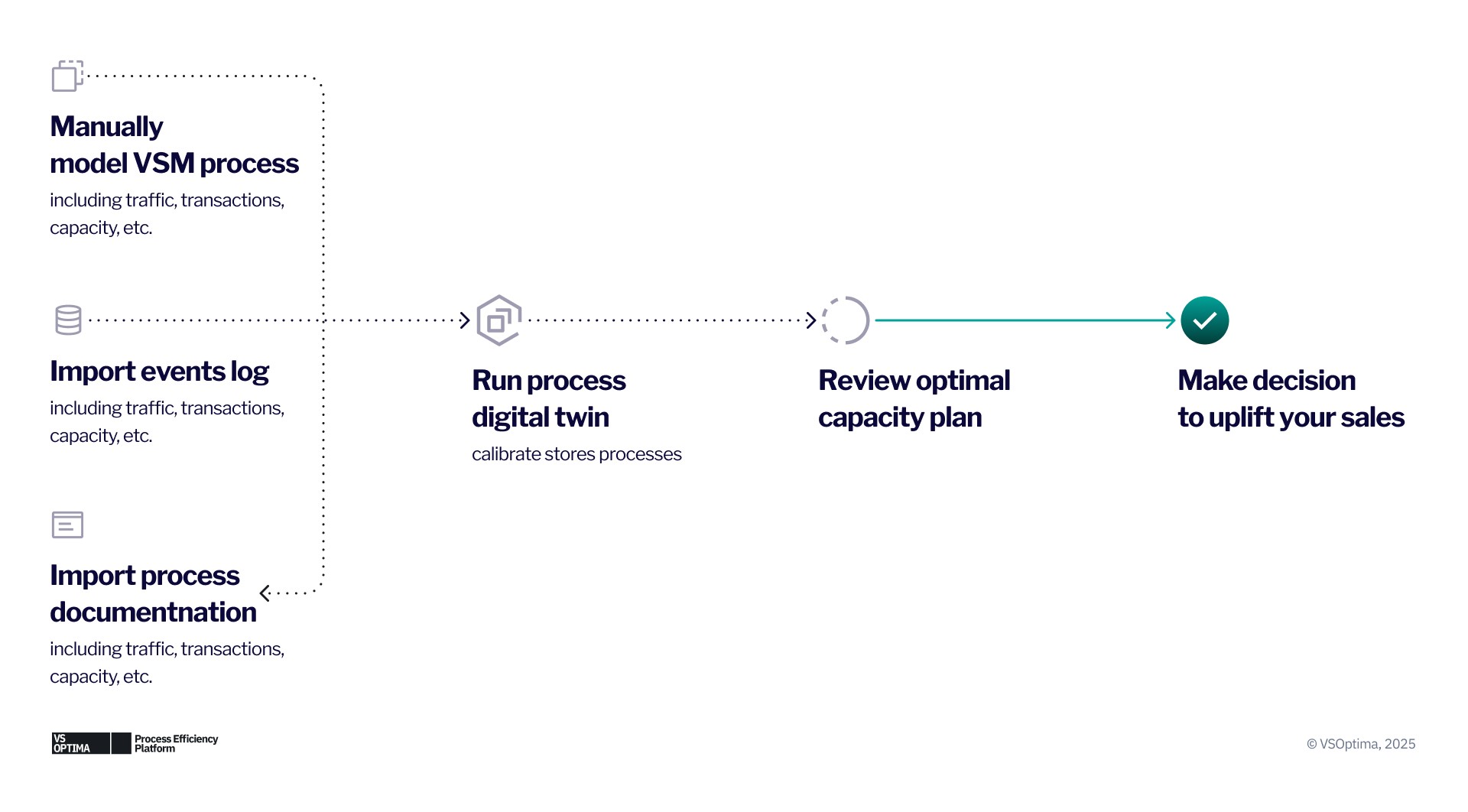

The right modeling approach depends on the nature of the process and the type of data available. There are three common approaches:

- Manual modeling is best for offline processes. As you will read in the case study below, a single customer journey model can be tuned for hundreds of stores using only three data points: process intake, process exit, and capacity. Imagine having a recipe all restaurants will use, but adjusting for each kitchen based on local tastes, tools, and ingredients available. This method captures store-specific behaviors like task timing, rework loops, and customer impatience without manual mapping.

- Event log-based modeling is ideal for digital processes. While similar to process mining, this method goes further by simulating scenarios and pinpointing the root causes of bottlenecks. It enables proactive decisions based on predictions, not just retrospective analysis.

- Text-based modeling is extracted from process documents using generative AI. By leveraging large language models, organizations can turn unstructured process documentation into structured and simulatable process models. It’s a fast, scalable way to digitize and optimize documented processes.

All three approaches accelerate the improvement cycle, moving from process mapping to scenario testing to decision-making in a fraction of the time traditionally required.

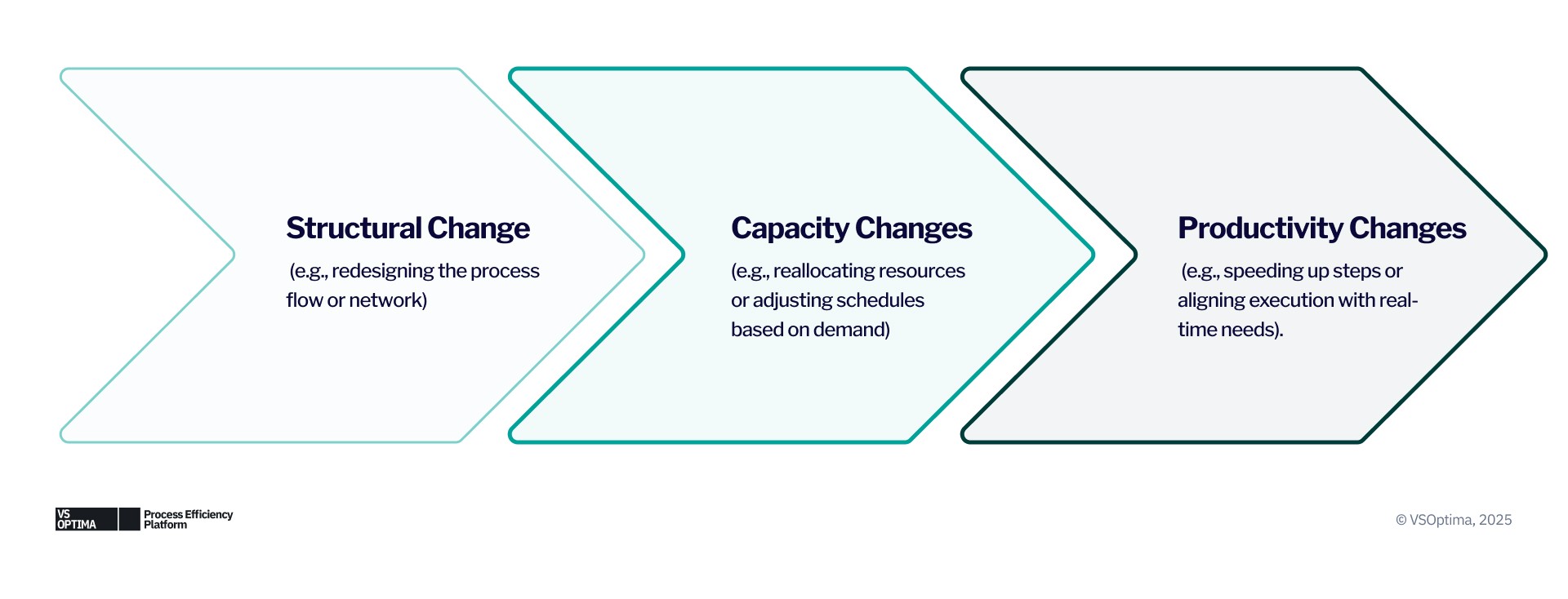

To get the most value from a process digital twin, organizations must clearly define the types of scenarios they want to test. These typically fall into three categories:

The key is to identify the primary constraint or bottleneck in the process first and then use the twin to simulate targeted interventions and their impact on performance.

Case Study: Scaling store operations with process digital twins

What does this look like in practice? Let’s use the example of a retailer my team worked with that wanted to boost workforce productivity without increasing headcount across hundreds of stores within the company’s network. The goal was to optimize labor allocation and maximize transactions per staffing level—a task that traditional methods of process improvement couldn’t address.

Historically, efforts to improve in-store operations relied on a mix of disconnected tools: spreadsheets, basic dashboards, and anecdotal observations. These were time consuming to maintain, lacked real-time accuracy, and rarely reflected the unique conditions of each store.

Process digital twins changed that.

The solution: Optimized operations using digital twins

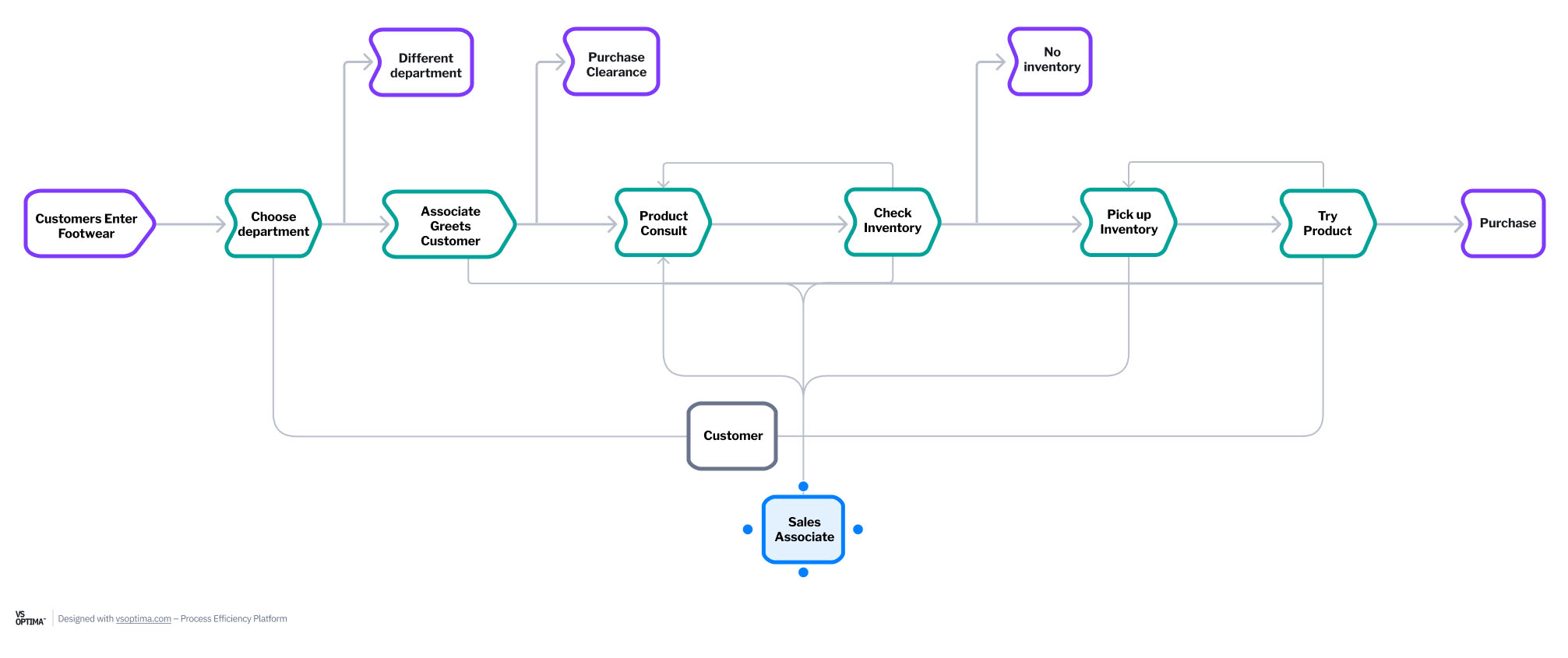

Instead of mapping each store manually, we started with a customer journey template, adjusted for store-specific conditions, and calibrated it using three data points: traffic, transactions, and staffing.

The system then inferred activity timing, customer backtracking, and employee and customer behavior dynamics specific to each store.

This enabled our team to generate customized, calibrated models for hundreds of the retailer’s stores in minutes — each one tailored to local conditions such as customer behavior and employee dynamics. Using this technique, we were able to help the retailer solve their productivity challenges and optimize staffing.

With process digital twins, the retailer gained a powerful platform for rapid experimentation with the ability to simulate and compare strategies across hundreds of locations. Each store’s model can be fine-tuned to reflect its unique environment, which has value far beyond staffing allocation and enables the retailer to predict the expected impact of each decision accurately before making operational changes.

The impact: Data-driven, scalable improvement

This approach improved store agility by using real-time market and operational data to better align labor allocation with shopper traffic and needs, ultimately driving higher sales. For example, during a regional promotion, the new system can simulate the expected traffic surge and recommend optimized staffing levels for each store to ensure sufficient floor coverage to capture demand without overstaffing.

As a result of using process digital twins, the retailer gained:

- As much as a 4.5% increase in foot traffic conversion to purchase

- Greater visibility into operations across all locations, enabling identification of both store-specific and system-wide issues

- The ability to more accurately allocate labor during marketing campaigns and promotions

By turning static process maps into dynamic, data-calibrated models, process digital twins enabled the retailer to shift from reactive problem-solving to proactive design — aligning decisions with the real-world complexity of their operations.

Taking the first step with process digital twins

The emergence of digital twins as a method for process improvement and optimization has revolutionized what was traditionally a static and manual initiative, creating endless opportunities for improvement through a dynamic, data-driven, and continuously optimized approach. By replacing slow, manual calculations with digital simulations, retailers can test operational changes in a virtual environment and confidently implement only the strategies that are most likely to succeed.

Our advice to retailers interested in this approach is to begin with a pilot: create one customer journey model, calibrate it with key data, and simulate a few operational scenarios. From there, scaling becomes a question of computing power, not manual effort, and the opportunities are endless.

However, building process digital twins requires more than just technology — it demands specialized expertise in data modeling, operations, and retail workflows. External experts can play a vital role in accelerating implementation, identifying the right modeling approach for each process, and ensuring the simulations are grounded in real-world behaviors. With the right guidance, retailers can unlock faster ROI, avoid costly missteps, and gain the insights needed to capitalize on the value digital twins have to offer.

Thinking about process optimization?

Meet the Author

Pavel Azaletskiy is a Catalant Expert and a technology executive and founder with more than two decades of experience enabling enterprise transformation through AI, data, and modern software delivery. Currently, as Founder and CEO of VSOptima, he works with leading retailers, insurers, and logistics firms to optimize labor allocation, cut transportation costs, and increase forecast accuracy using AI and digital twins. Azaletskiy holds a Master of Business Administration from UCLA and a Master of Science in Computer Science from Saint Petersburg State University of Aerospace Instrumentation.